Description of prickly pear processing line

1.A wide range of raw materials, this production line is suitable for all kinds of large and small fruit Rosa Roxburghii;

2. The configuration of production line is flexible, and different functional equipment, such as enzymatic hydrolysis, membrane filtration and concentration equipment, can be flexibly configured according to different final product requirements of customers;

3. According to different investment amount and product positioning of customers, customers can configure ordinary, middle end or high-end products according to their own requirements;

4. The final product has good flavor, bright color and high yield;

5. The whole line has high degree of automation, low labor intensity, simple operation, reliable performance and low operation cost;

6. The whole production line adopts sanitary design, with thorough cleaning and high hygiene level.

Product Specification| Raw material | Big or small fruit Rosa Roxburghii (with or without branches) |

| End product | concentrated juice, clear juice, turbid juice |

| Production capacity | 20T/D-2000T/D |

| Output percentage | ≥90% |

| Solid content | 10~15Brix |

| Packing type for end product | Aseptic Bag/glass Bottle/PET Bottle /roof bag / Tetra Pak |

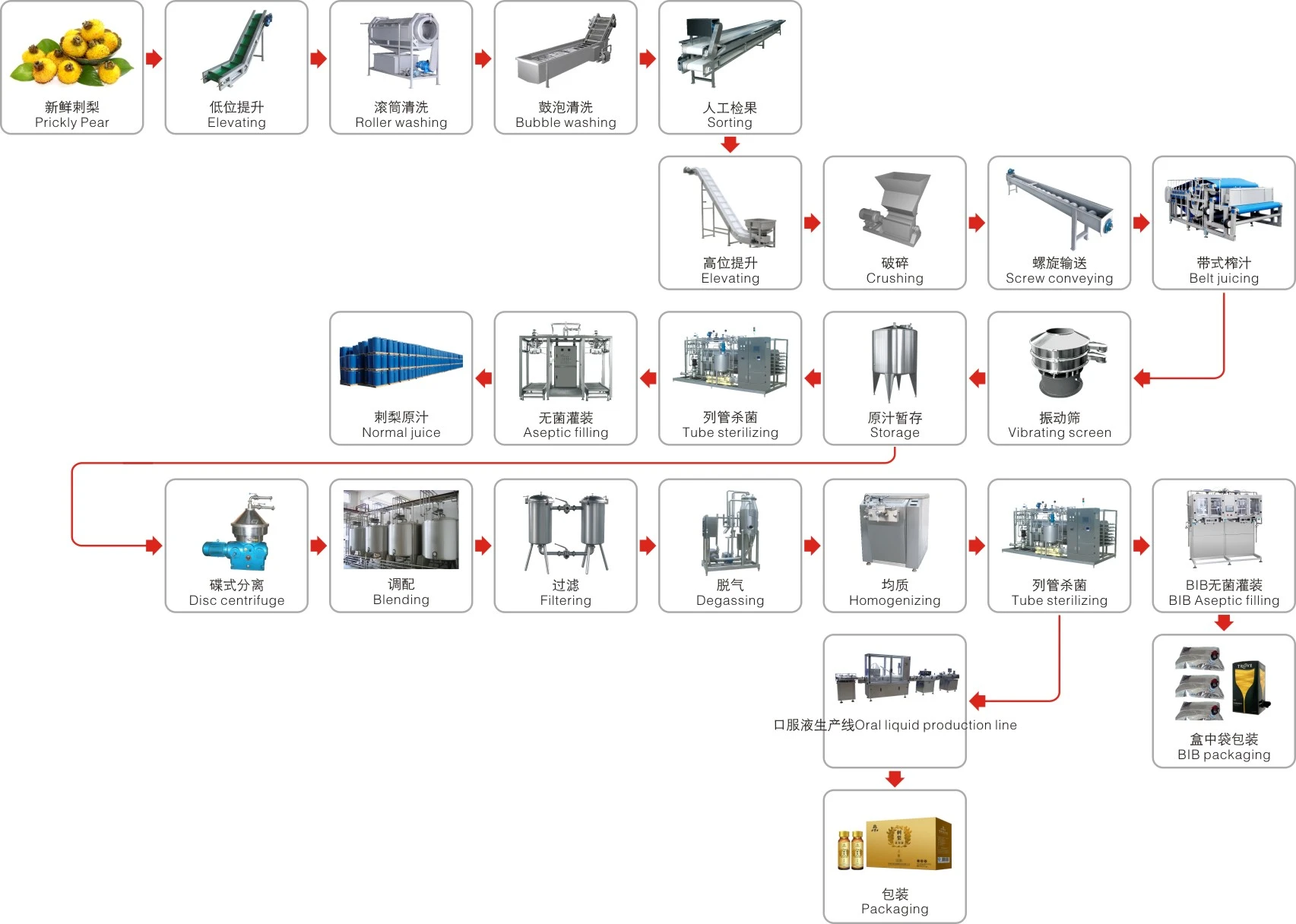

Product Flowchart1.Prickly Pear--Elevating--Roller washing--Bubble washing--Sorting--Elevating--Crushing--Screw conveying--Belt juicing--Vibrating screen--Storage--Tube sterilizing--Aseptic filling--Normal juice.

2.Prickly Pear--Elevating--Roller washing--Bubble washing--Sorting--Elevating--Crushing--Screw conveying--Belt juicing--Vibrating screen--Storage--Disc centrifuge--Blending--Flitering--Degassing--Homogenizing--Tube sterilizing--(BIB Aseptic filling--BIB packaging)--Oral liquid production line--Packaging.