Description of Pineapple Processing Line

1.Firstly, pineapple is a famous tropical fruit. Because of its delicate flesh and unique flavor, it is deeply loved by people. So it is known as the"king of tropical fruits".

2.The equipment of pineapple processing plant is to process fresh pineapple into concentrate clear juice and cloudy juice after cleaning, peeling and coring, beating, crushing, juicing, enzymatic hydrolysis, membrane filtration, concentration, sterilization, filling and other processes, and then pack the fresh pineapple into juice, and pack it into aseptic bag in drum as semi-product. At the same we can mixing the concentrate into juice drinking and filling in various containers such as PET bottle, glass bottle,Tetra Pack, roof bag,stand-up pouch etc., so as to achieve the purpose of cold chain or normal temperature sales.

3.Secondly, pineapple can be processed into jam after washing, peeling and coring, crushing, cutting, mixing and boiling,filling, pasteurizing and packing processes, packages could be glass bottle, metal can, stand-up pouch etc.

4.Thirdly, pineapple also can be processed into cans pineapple and chunks which filled into glass bottle or metal can. * The capacity of pineapple processing line can be 10tons to 480 tons per day.

Features of Pineapple Processing Line

* Advanced technology and energy saving.

* SUS304/316L material,high qualified component of international brand.

* Semi-automatic as well as fully automatic system available.

* Customized turn-key solution including installation, commissioning at your factory.

* The finished product quality is excellent, and the color is delicious.

* High productivity, flexible production, can be customized according to customer demand.

* Complete supervision system, equipped with control room to monitor each processing stage.

* Daily output can be clearly record.

Product Specification| Raw material | Fresh pineapple |

| End product | Concentrated juice, clear juice |

| Processing capacity | From 10 tons/day to 480 tons/day |

| Efficient input | About 65% raw fruit (35% as waste, peels and seeds) |

| Fruit consistence | 10~12% Brix |

| Product consistence | 65~72% Brix for concentrated juice |

| End package | Aseptic bag/ Tin can/ Glass bottle/ PET bottle/ Stand-up pouch, etc |

| Output | Can be calculated |

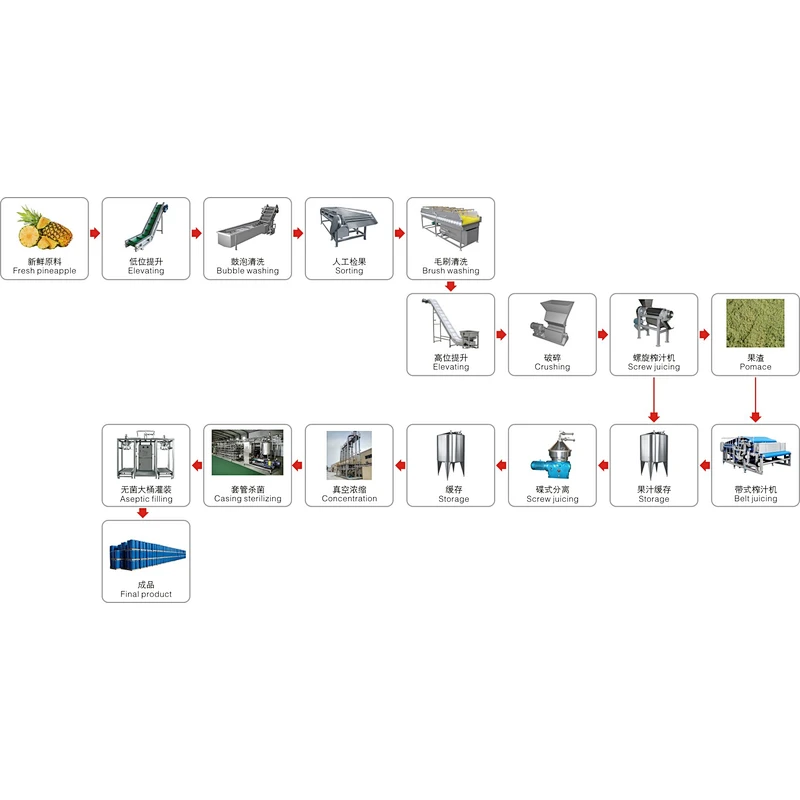

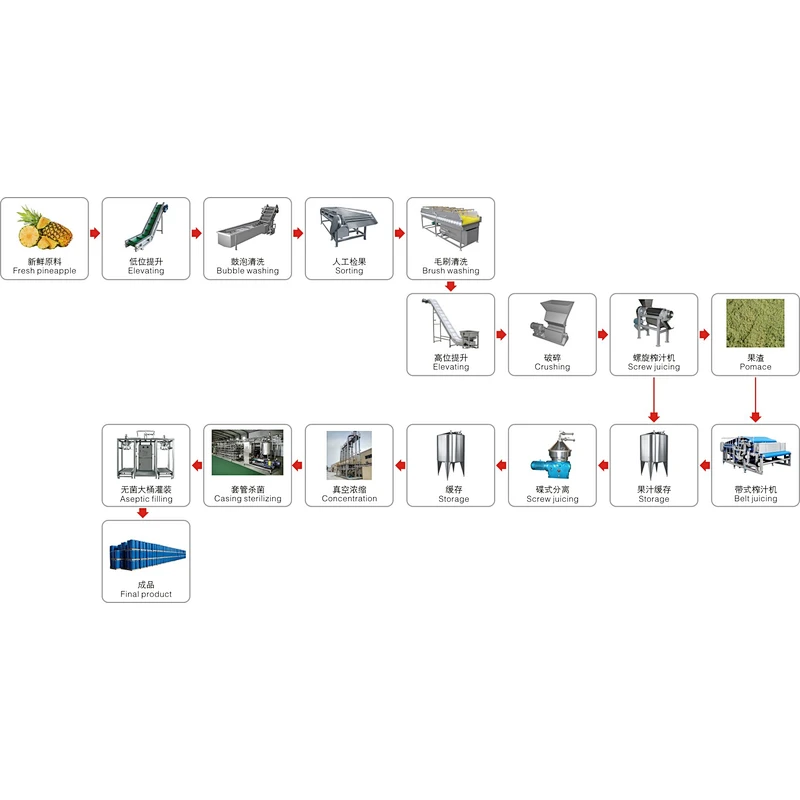

Product FlowchartFresh pineapple--Elevating--Bubble washing--Sorting--Brush washing--Elevating--Crushing--Screw juicing--(Pomace-Belt juicing)--Storage--Screw juicing--Storage--Concentration--Casing sterilizing--Aseptic filling--Final product.