Description of Peach/ Apricot/ Plum Processing Line

1. Peach/ Apricot/ Plum and other stone can be processed to pulp, puree, paste, jam, clear concentrate juice, concentration pulp, fruit powder, fruit vinegar, and other products.

2. Peach/ Apricot/ Plum processing line composed of washing and sorting system, destoning and pulping system, enzymatic hydrolysis and filtering system, evaporating system, sterilizing and aseptic filling system, blending and repackaging system, auxiliary energy system, etc.

3. Peach/ Apricot/ Plum processing line capacity is from 60 tons/day to 480 tons/day.

4. Peach/ Apricot/ Plum pulp yield: About 65%~75% (25%~35% for fruit peels and cores for the waste)

5. Raw material solid content: 10-14% Brix. Final concentrated juice concentration: 65~72% Brix, Concentrated paste 28~30% Brix.

Features of Peach/ Apricot/ Plum Processing Line

* Advanced technology, energy & water saving.

* SUS304/316L material, high qualified component of international brand.

* Semi-automatic and fully automatic system for your choice.

* Customized turn-key solution including installation, commissioning at your side.

* The finished product quality is excellent, beautiful color and tasty.

* High productivity, flexible production, can be customized according to customer demand.

* Complete supervision system, equipped with control room to monitor each processing stage.

* Daily output can be clearly record.

Product Specification| Raw material | Fresh Peach/ Apricot/ Plum |

| End product | Puree, juice concentrate, concentrate pulp, paste, jam |

| Processing capacity | From 10 tons/day to 2000 tons/day |

| Brix of juice | 11~15% Brix |

| Brix of concentrate | 30~65% Brix |

| End package | Aseptic bag/ Metal can/ Glass bottle/ PET bottle/ Pouches |

| Designed capacity | According to clients' requirements |

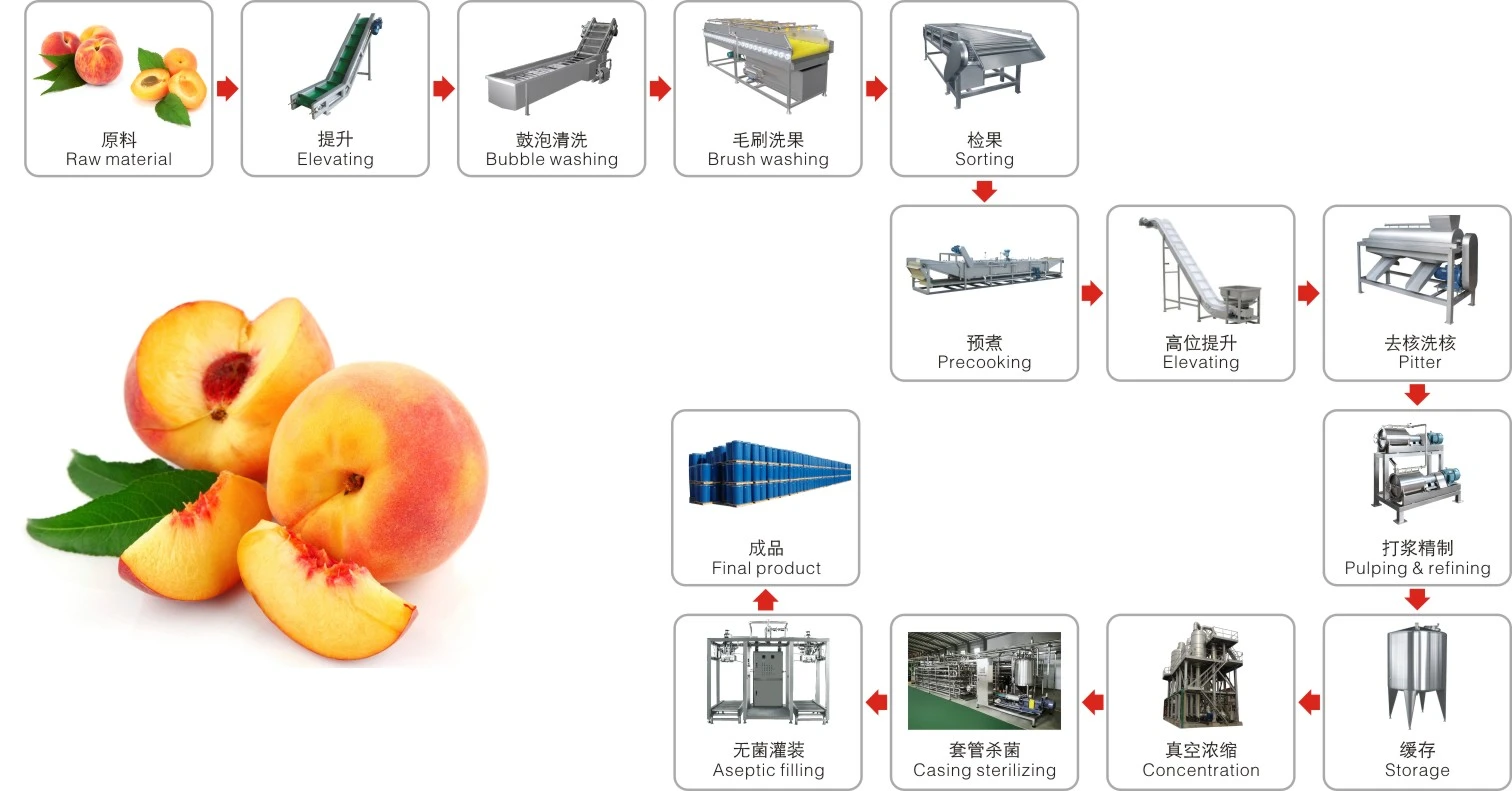

Product FlowchartRaw material--Elevating--Bubble washing--Brush washing--Sorting--Precooking--Elevating--Pitter--Pulping&refining--Storage--Concentration--Casing sterilizing--Aseptic filling--Final product.