Description of Coconut Processing Line

1. Coconut is rich in fat and nutrients. Copra meat contains 3.4%~4.0% protein, 30%~40% fat, and dry coconut meat contains 50%-70% oil. In addition, coconut meat also contains carbohydrates, fiber, minerals, vitamins and other nutrients. Coconut water is a high-grade refreshing drink, which contains 0.1% protein, 0.1% fat and 4% carbohydrate.

2. Our coconut processing line includes coconut dipping and washing system, coconut water extraction, filtration and pasteurization system, coconut meat cleaning, blanching, sorting and coconut milk extraction system, coconut milk blending, sterilizing and filling system, coconut water evaporating, sterilizing and filling system, CIP cleaning system, RO water generating system.

3. Our coconut production line has high flexibility, it can produce coconut cream and coconut milk, single strength and concentrated coconut water, virgin coconut oil, desiccated coconut, coconut milk powder by adjusting the technological flowchart and machine.

4. The final package of the coconut products can be Aseptic bag, Tin can, PET bottle, Glass bottle and other consumable packages can be used for packing coconut products according to client requirements.

5. The capacity of the coconut processing line is from 500 to 10000L/H available.

Features of Coconut Processing Line

* Advanced technology, energy & water saving.

* SUS304/316L material, high qualified component of international brand.

* Semi-automatic and fully automatic system for your choice.

* Customized turn-key solution including installation, commissioning at your side.

* The finished product quality is excellent, beautiful color and tasty.

* High productivity, flexible production, can be customized according to customer demand.

* Complete supervision system, equipped with control room to monitor each processing stage.

* Daily output can be clearly record.

Product Specification| Raw material | Coconut |

| End product | Coconut juice, Coconut milk, Coconut water, Coconut powder |

| Processing capacity | 500-10000L/H |

| End package | PET bottle/ Tin can/ Tetra pack |

| Designed capacity | According to clients’ requirements |

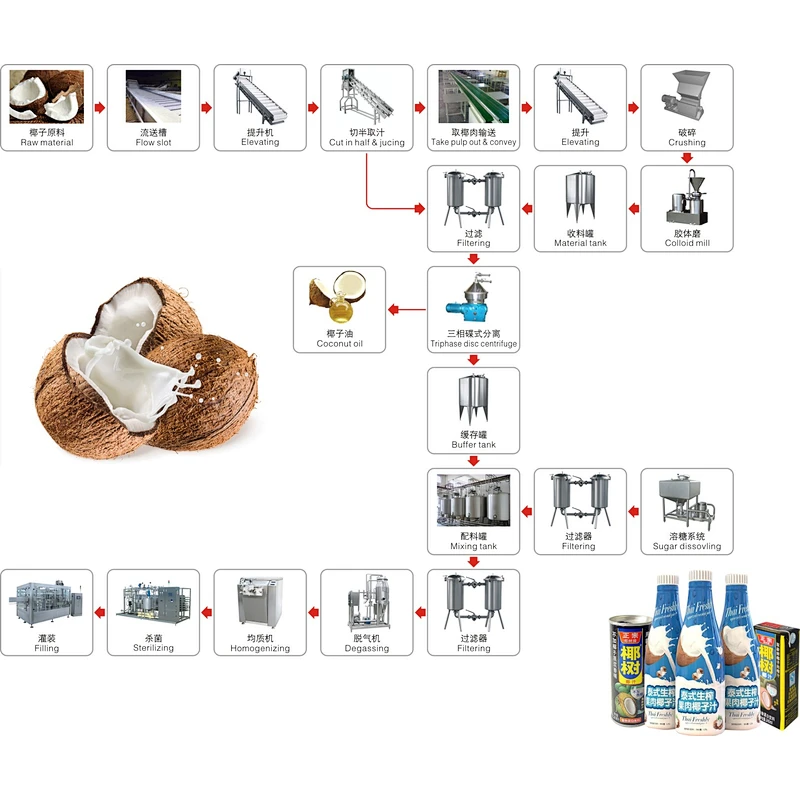

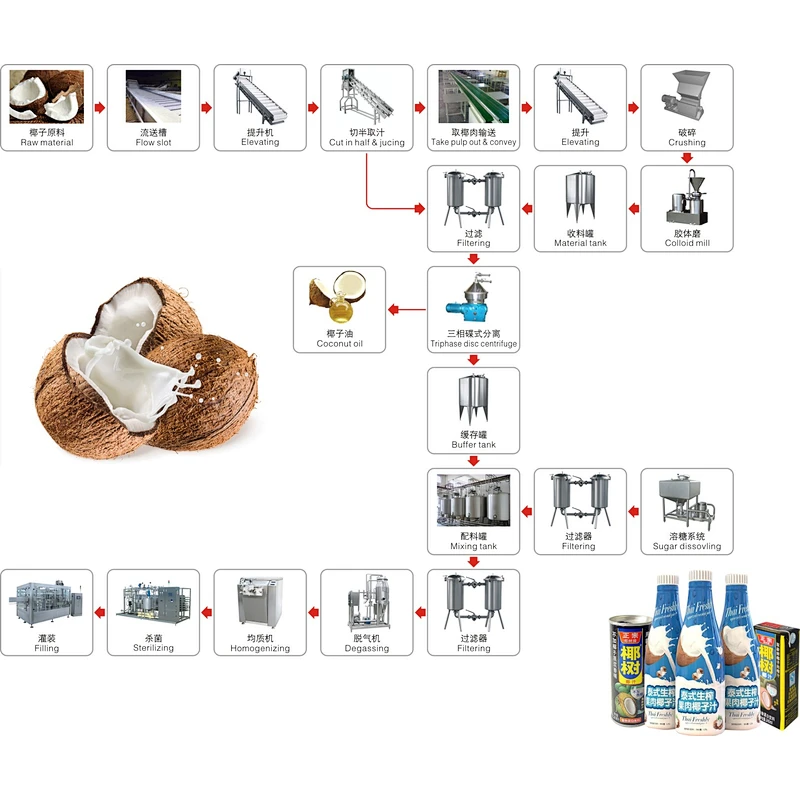

Product FlowchartRaw material--Flow slot--Elevating--Cut in half&jucing--Take pulp out&convey--Elevating--Crushing--Colloid mill--Material tank--Filtering--Triphase disc centrifuge--Buffer tank--Mixing tank--Filtering--Degassing--Homogenizing--Sterilizing--Filling.

Raw material--Flow slot--Elevating--Cut in half&jucing--Filtering--Triphase disc centrifuge--Coconut oil.