Welcome to visit our website

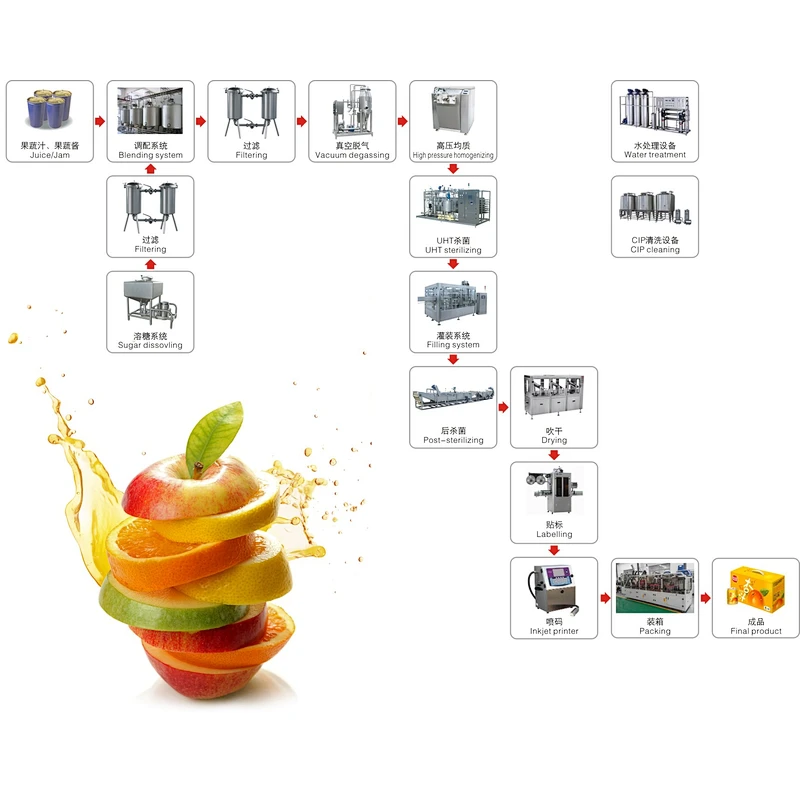

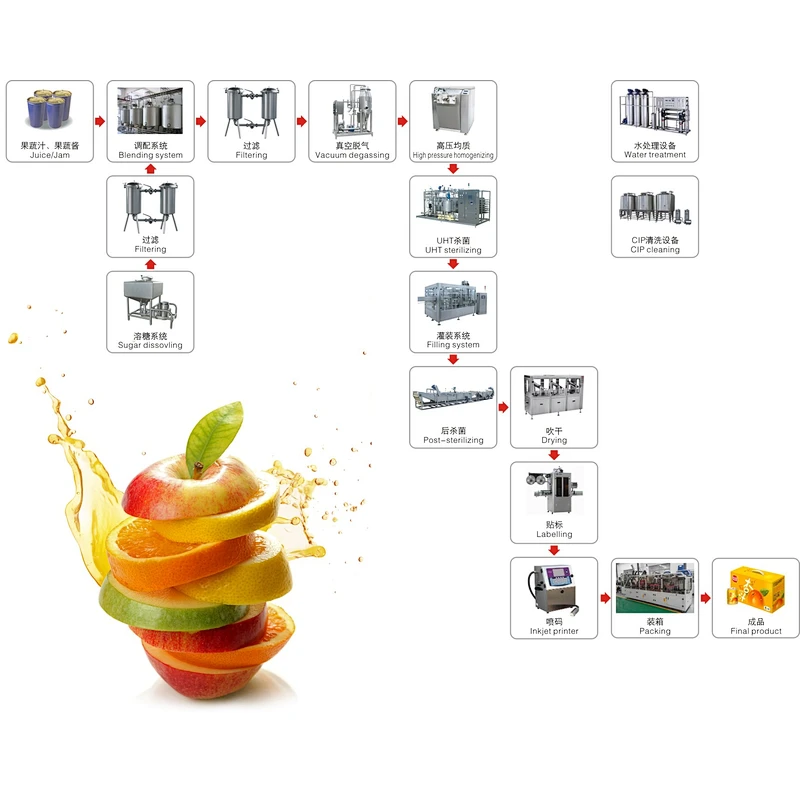

Topking---We always take "honesty, Moderation, Innovation and High-efficiency" as tenet to improve ourselves.About UsWuxi City, Jiangsu Province, ChinaWuxi Topking Machinery S. & T. Co., Ltd. is an integrated high-tech industrial company involved with scientific research and design, manufacture and technical service in the line of food machinery. We have designed and developed advanced complete sets of food machinery used to process nuts, vegetable, fruit, juice, sauce & butter, snack food, puffed food, spice and so on. Due to past achievement on exploring vast international market, we have obtained the European CE Certificate, SGS Certificate, HACCP Certificate. Our company has our own top-ranking production base and the

TK-YLBZH

0.00~0.00

TK-YLBZH

0.00~0.00