Description of Apple/ Pear Processing Line

1. Fresh apple and pear can be processed to apple/pear pulp, puree, NFC juice, HPP juice, clear concentrate juice, concentrate paste, jam, sauce,etc;

2. The apple and pear processing includes washing and sorting system, crushing and color protection system, juice /pulp extracting system, decanting and standardization system, enzymatic hydrolysis and filtration system, evaporating system, sterilizing system and aseptic filling system.

3. Apple/pear processing line capacity is from 24 tons/day to 480 tons/day.

4. Apple/pear Juice yield: about 75% (25% for fruit peels and cores for the waste).

5. Raw material solid content: 12~14% Brix, Final concentrated juice concentration: 65~72% Brix, Concentrated apple paste 28-30% Brix.

Features of Apple/ Pear Processing Line

* Advanced technology, energy & water saving.

* SUS304/316L material, high qualified component of international brand.

* Semi-automatic and fully automatic system for your choice.

* Customized turn-key solution including installation, commissioning at your side.

* The finished product quality is excellent, beautiful color and tasty.

* High productivity, flexible production, can be customized according to customer demand.

* Complete supervision system, equipped with control room to monitor each processing stage.

* Daily output can be clearly record.

Product Specification| Raw material | Fresh apple, pear, similar fruits |

| End product | NFC juice, pulp puree, Concentrated juice, clear juice, cloudy juice, Jam |

| Processing capacity | From 24 tons/day to 2000 tons/day |

| Efficient input | 75% raw fruit (25% as waste,peels and seeds) |

| Fruit consistence | 10~12% Brix |

| Product consistence | 65~72% Brix for concentrated juice |

| End package | Aseptic bag/ Metal can/Glass bottle/PET bottle |

| Output | Can be calculated |

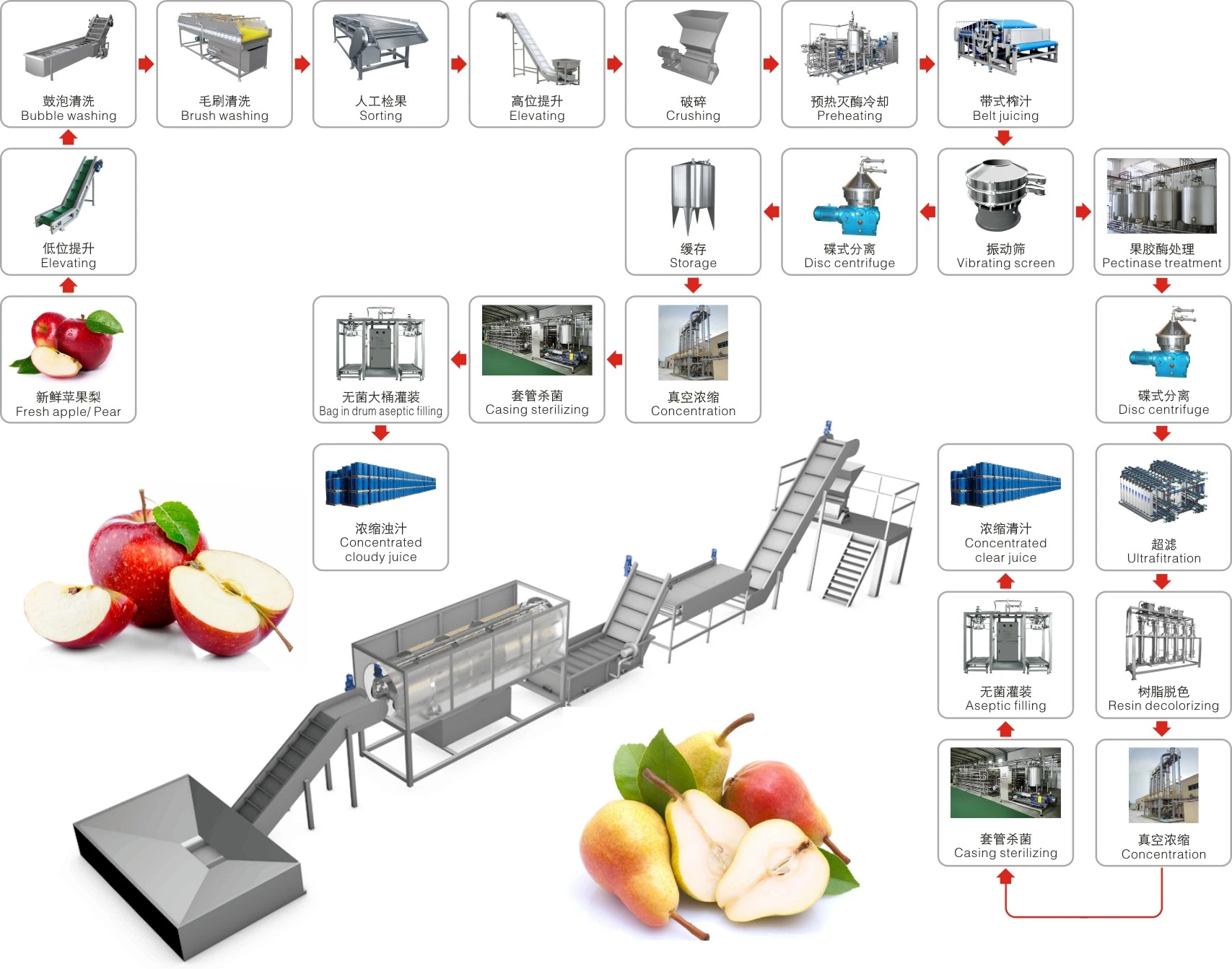

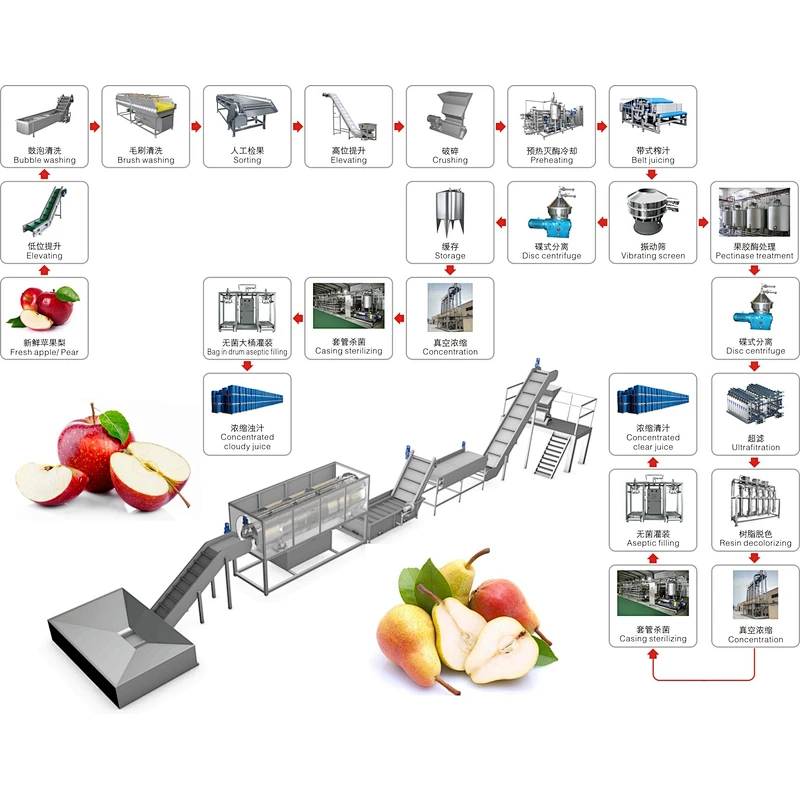

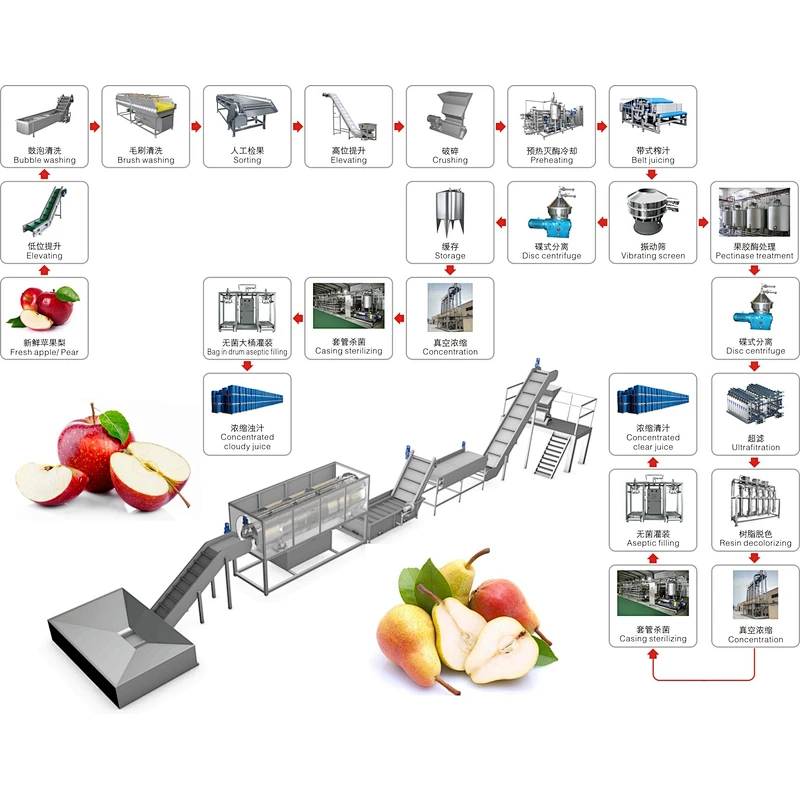

Product Flowchart1.Fresh apple/Pear--Elevating--Bubble washing--Brush washing--Sorting--Elevating--Crushing--Preheating--Belt juicing--Vibrating screen--Disc centrifuge--Storage--Concentration--Casing sterilizing--Bag in drum aseptic filling--Concentrated cloudy juice.

2.Fresh apple/Pear--Elevating--Bubble washing--Brush washing--Sorting--Elevating--Crushing--Preheating--Belt juicing--Vibrating screen--Pectinase treatment--Disc centrifuge--Uitrafitration--Resin decolorizing--Concentration--Casing sterilizing--Aseptic filling--Concentrated clear juice.